Combined

C.O.S.M.A.P.’s most distinctive feature throughout the years, along with the great reliability, is the possibility to combine our polishing and grinding process know-how into more and more innovating and performing solutions.

This section is about those machines that are capable of performing the entire grinding and buffing processes without the need to stop between the two, nor the need for manual processing in between. Basically composed of indexed rotary tables or robotized systems, during the last few years the solutions employing both the systems are becoming more and more popular.

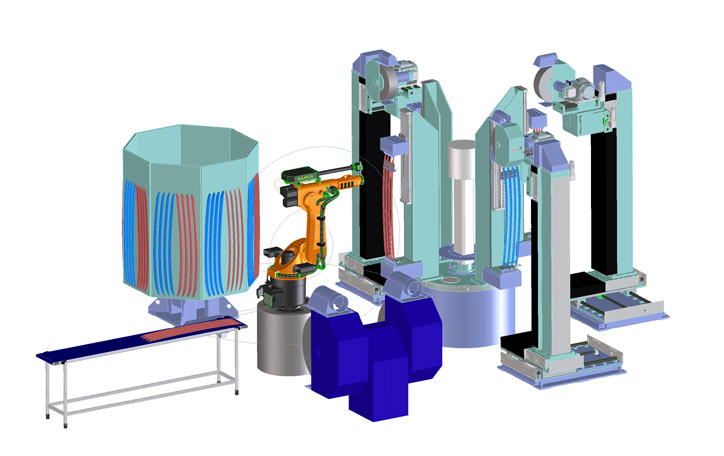

Robotic Cell and Rotary Table

The most complete and performing solution for flexibility, process and productive capacity.

A spreading solution reassuming the concept of Lean Manufacturing and processing efficiency, plus the robot-equipped with a grinding isle and the rotary table for polishing. Two dramatically different concepts bound by one characteristic: the cycle time management. This solution is based on the idea of hiding any processing step within the same cycle time. The aim is to synchronize the fast grinding process with the slower polishing process.

Each turn will deliver a grinded, polished, and therefore finished piece. The automated isle’s grinding flexibility and the rotary table’s polishing efficiency make the processing isle the best, synergic solution to optimize the production process. Each isle can be designed with an automatic loading/unloading system accordingly to the product nature: Double pallet system, belt, vertical/drum loader, just to mention some.

The automated isles can be single, double or triple according to the client’s productive necessities.

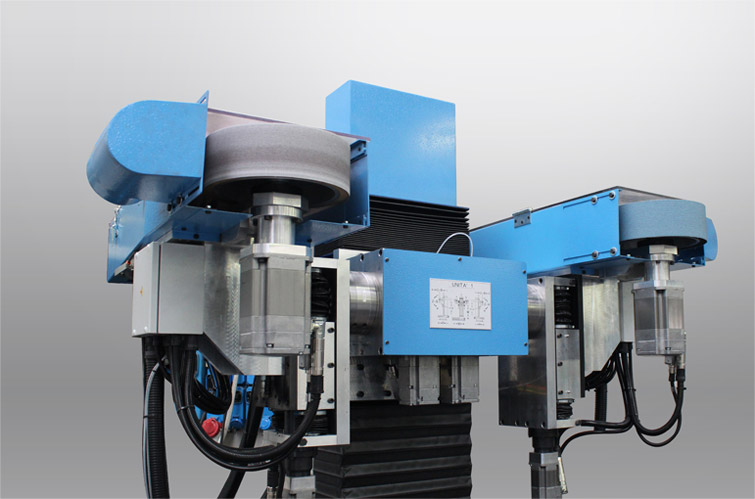

Indexed Rotary Tables

Indexed rotary table with C.N.C.S. type grinding/linishing unit and polishing C.N.C.

A highly productive combination, with a great flexibility in process management and complex surface treatment. A technological evolution that combines the indexed rotary table characteristics with the innovative and flexible CNCS grinding and CNC polishing units. This solution is to consider as the first step to Lean Manufacturing. The combination of two distinct processes, with opposed characteristics and, most importantly, the possibility to hide the loading cycle time makes this kind of machine the ultimate expression of flexibility and productive capability. Thanks to this solution, it is possible to go through the grinding and polishing process using the indexed rotary table with the advantage of executing an entire process with hidden cycle times.

Custom solutions

Listen to the needs of our Customer and answer with all our experience and with the most advanced technologies. COSMAP has always been distinguished by the flexibility and accuracy when facing every challenge involving the processing of metal and non-metal products.

The intensive study of the grinding and polishing process whether manual or automated, and a strong inclination to a better technological, mechanical and electronic research gave birth to great developments and solutions. During the past thirty years of this company’s history, we tried to treasure every single experience regarding the process and the technological solutions, trying more and more often to improve and combine these two factors.