Automatic polishing machines

Polishing

To create automatic machines for buffing, polishing and satin finishing metals and more, is from the very beginning of our story the most important field of application.

Basically composed of indexed rotary tables or continuous motion tables, they may be equipped with a vast selection of buffing units featuring different degrees of complexity, flexibility, and process management. Within this section, you will find some of our solutions, divided by distinguishing features that are needed to cope with any kind of processing need, in a very innovating and competitive way.

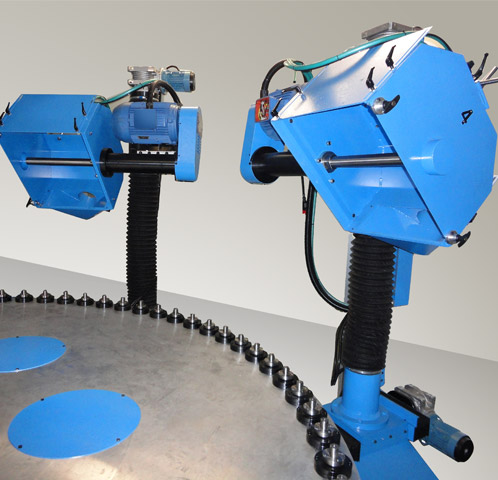

Indexed rotary tables

A technological evolution in the field of automatic metal polishing with rotary table systems. Our C.N.C: type polishing units represent a technological evolution -entirely carried on and developed by C.O.S.M.A.P.- in the world of the automatic metal polishing on a rotary table. Featuring 5 electronic axes (linear and rotary) combined with the 2 on the rotary table, the C.N.C.s are capable of a high number of movements.this allows the buff to approach any kind of workpiece, even ones with complex geometries.

Continuous rotation table with C.P.L. type polishing unit

The most widespread –and most productive– product when it comes to polishing, constantly updated to keep up with the new demands of this field and with the new technologies. A traditional polishing machine that gets its high productivity on the continuous rotation of the rotary table and its fixtures. Featuring a large number of spindles, this machine is highly productive especially when working with workpieces that possess regular and even geometric shapes. The polishing units to be positioned around the rotary table may vary in complexity and capability, according to the production needs: adding more simple or servo-controlled axes that will grant different degrees of movement. To allow a faster production change, all the units are pre-set to be equipped with the auto-positioning function. (pop-up auto posizionamento, come per le altre sezioni) To perform special polishing and mirror finishing processes, special manual-adjustable, working position-bound counter locks can be added. An additional, lightweight polishing unit can be positioned at the center of the Rotary Table.

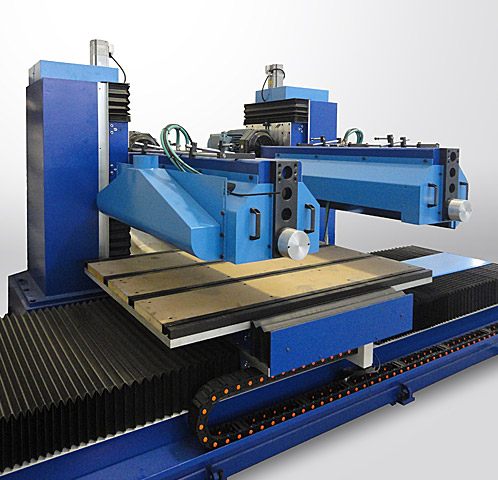

Flatbed Machines

The simplest and most efficient solution for the polishing of metal surfaces, still proposed as the cutting edge in this field becoming more and more performing. The mobile bench or static bench solutions can be associated with any kind of polishing unit, from the basic ones needed to operate on a linear surface to the most complex CNC ones. The necessity to find a way to perform the loading/unloading task within hidden times, meaning during the simultaneous processing of the same amount of pieces, is very important for these units, too. The static bench is to intend with the possibility to get a gripper to remain steady and static while the piece moves to a different working station, or the opposite. The polishing unit may either be equipped with a simple axis that pneumatically checks the working pressure, therefore setting the adequate contact wheel position according to the position of the currently processed piece (thanks to controlled servo-axes), or with up to nine axes that can be interpolated between the axes of the unit and those of the fixture. An automatic tool rack may be attached to multi-axis units, allowing the utilization of a single unit capable of switching between up to ten tools, allowing going through an entire process without the need to shift between different units or increasing their number.

Custom solutions

Listen to the needs of our Customer and answer with all our experience and with the most advanced technologies. COSMAP has always been distinguished by the flexibility and accuracy when facing every challenge involving the processing of metal and non-metal products.

The intensive study of the grinding and polishing process whether manual or automated, and a strong inclination to a better technological, mechanical and electronic research gave birth to great developments and solutions. During the past thirty years of this company’s history, we tried to treasure every single experience regarding the process and the technological solutions, trying more and more often to improve and combine these two factors.